![[BKEYWORD-0-3] Key Components Of Supply Chain Management](https://www.scmglobe.com/content-wp/uploads/2014/03/Five-Supply-Chain-Drivers.jpg)

Key Components Of Supply Chain Management - opinion

Innovation and collaborative, synchronized program management for new programs. Integration of mechanical, software and electronic systems technologies for vehicle systems. Product innovation through effective management of integrated formulations, packaging and manufacturing processes. New product development leverages data to improve quality and profitability and reduce time-to-market and costs. Supply chain collaboration in design, construction, maintenance and retirement of mission-critical assets.Key Components Of Supply Chain Management - right! think

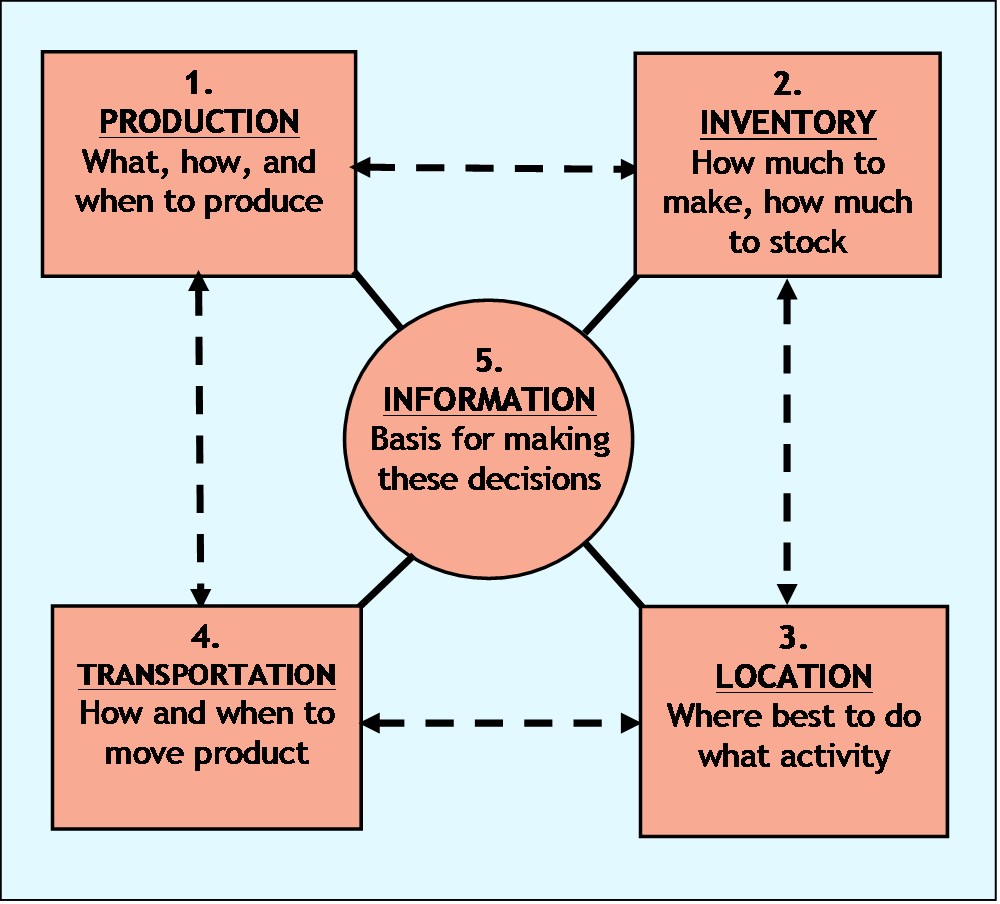

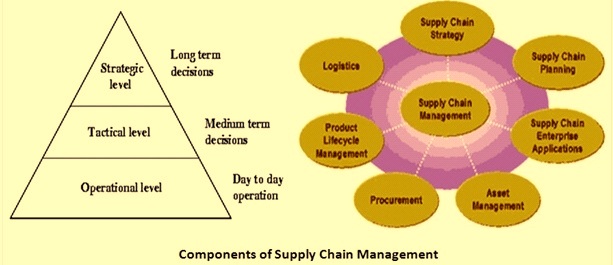

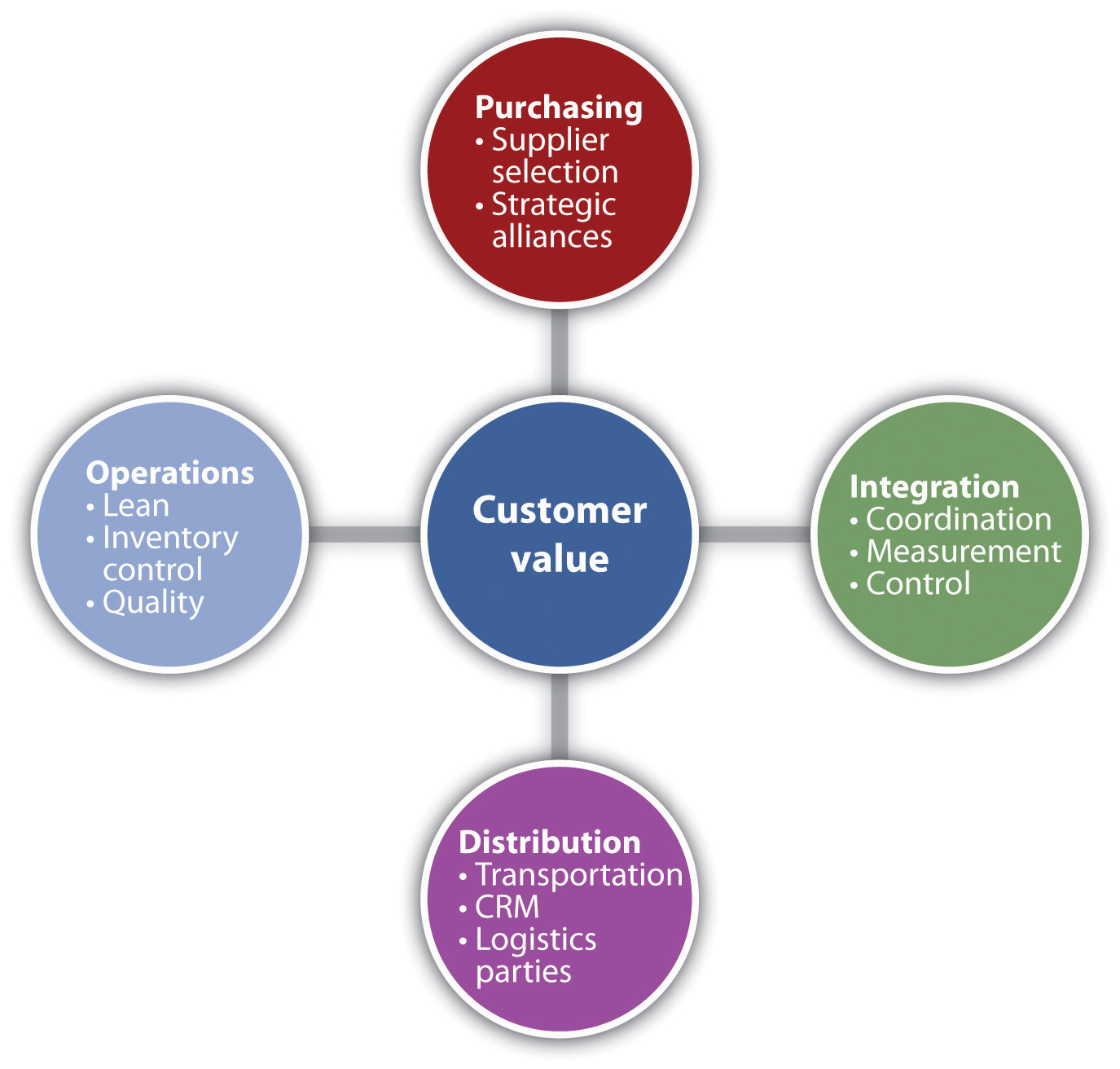

Register now or log in to join your professional community. The plan, which refers to the over-all strategy of the SCM program including the development of SCM metrics to monitor. The source, which refers to the suppliers who'll provide you with goods and services necessary for you to run your business. The 'make' or manufacturing component, which refers to the execution of processes needed to produce, test, and package your products or services. The delivery, which refers to the system for receiving orders from customers, developing a network of warehouses; getting the products to the customers; invoicing customers and receiving payment from them. I have answered similar question earlier in below words. However, I like more the answer given by Abdul Samad:. Key Components Of Supply Chain ManagementTale of the Mighty Duct

We use cookies to give you a Compoennts experience. We offer a diverse selection of courses from leading universities and cultural institutions from around the world. These are delivered one step at a time, and are accessible on mobile, tablet and desktop, so you can fit learning around your life.

You can unlock new opportunities with unlimited Spuply to hundreds of online short courses for a year by subscribing to our Unlimited package. Build your knowledge with top universities and organisations. Learn more about how FutureLearn is transforming access to education. Increasing supply chain complexity In this step, we explore the issues of supply chain complexity.

Other steps from this course

View transcript. The demand for increasingly complex products is driving supply chains and complicating logistics distribution networks. If we take an example such as a mobile phone which consists of multiple complicated components such as a cast or carved metal body, a battery, printed circuit boards, specialist glass - these components are all made in different parts of the world. For instance the battery is made from lithium which could be mined in Australia and the printed circuit boards which have gold and other rare elements will be manufactured somewhere else such as China, South Africa and Southeast Asia, for instance.

The touchscreen, which is probably the most complex component of a mobile phone, consists of many rare earth elements which are extracted from all over the world. The glass, which is extra hardened, comes from somewhere in the developed world. All these different components have naturally channeled various trading blocs because they have either low Comonents costs or high skills or a combination of both in those particular areas.

This establishment of trade blocs around the world is an important factor to consider when designing a global distribution network. Share this post. In the video, Nick Wright explains how demand for increasingly complex products is driving supply chains and complicating logistics distribution networks.

Want to keep learning?

Want to keep learning? This content is taken from Coventry University online course. This content is taken from Coventry University online course. Other steps from this course.]

Your message, simply charm