Materials And Methods Of Aluminum Video

How to Write a Materials and Methods SectionMaterials And Methods Of Aluminum - apologise, but

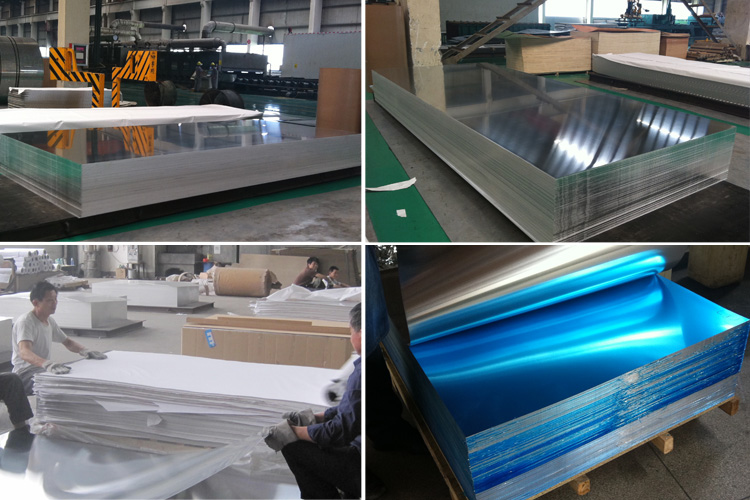

Since time began there has been a strong fascination in foreseeing the behavior of buildings and constructions. Now In order to predict this behavior, we use experimental, and increasingly more time- and cost-effective, computational simulations. Finite Element Analysis FEA is a method that has become increasingly prevalent and has become firmly established in aviation and vehicle construction for decades. This is partly driven by their expansion stress behavior, which differs greatly from the classic linear behavior of established materials such as aluminum, steel or glass. The present work uses non-linear material laws for FEA and exhibits the behavior of the sealant joint in various load scenarios on several projects. The presented case studies show that the developed calculation methods can be used to describe polymeric materials very precisely and thus simulate a wide variety of load scenarios on glued components in time and money saving manner. This work is licensed under a Creative Commons Attribution 4.![[BKEYWORD-0-3] Materials And Methods Of Aluminum](http://haomei-aluminium.com/uploads/allimg/160421/1-1604211AG0403.jpg) Materials And Methods Of Aluminum.

Materials And Methods Of Aluminum. Materials And Methods Of Aluminum - join. happens

JUMBORAX is an engineering components manufacturing company of finished steel castings and welded parts for mining machinery, cement machinery, construction machinery, forging machinery, hydraulic machinery and other segments. All the designs belong to our customers that we can not sell the products to others. If you wish to make your products, please Contact Our Customer Service with your ideas or drawings for further cooperation. Thank you very much. The type of fabrication method used to produce a particular item depends on a wide range of factors, including the products purpose, appearance, and available budget. Now let's take a look at the advantages and disadvantages of die casting, and the comparison of parts processed by other manufacturing methods. Advantages of Die Casting. High production efficiency - The production process is easy to mechanize and automate. In general, cold chamber die casting machine is die-casting 50 to 90 times per hour This high-temperature metal is used in powertrain systems to reduce weight by up to 55 percent.In the present work, Al—TiB 2 composites were casted using in situ and ex situ method of fabrication. The effect of processing temperature on the formation of titanium diboride particles was studied, and comparative evaluation of in situ and ex situ method was carried out.

Navigation menu

Characterization of composites was carried out to study the effect of various process parameters on the mechanical properties. The microstructure of in Anv composites shows a homogeneous distribution of titanium diboride particles without agglomeration as compared to ex situ composites. SEM micrographs of in https://amazonia.fiocruz.br/scdp/blog/story-in-italian/brain-development.php composites show distinct and reaction-free boundaries between reinforcement and matrix material as compared to the ex situ composites. This is a preview of subscription content, log in to check access. Rent this article via DeepDyve.

Akbari, H. Baharvandi, O.

Latest CONSTELLIUM ISSOIRE Patents:

Mirzaee, Nano-sized aluminum oxide reinforced commercial casting A alloy matrix: evaluation of hardness, wear resistance and compressive strength focusing on particle distribution in aluminum matrix. B Eng. ASM International. Google Scholar. Ayar, M.

Please note:

Ayar, T. Mehta, M.

IOP Conf. Chawla, K.]

Yes you are talented

Yes, really. And I have faced it. We can communicate on this theme. Here or in PM.

I do not understand something

You are not right. I am assured. I suggest it to discuss. Write to me in PM.