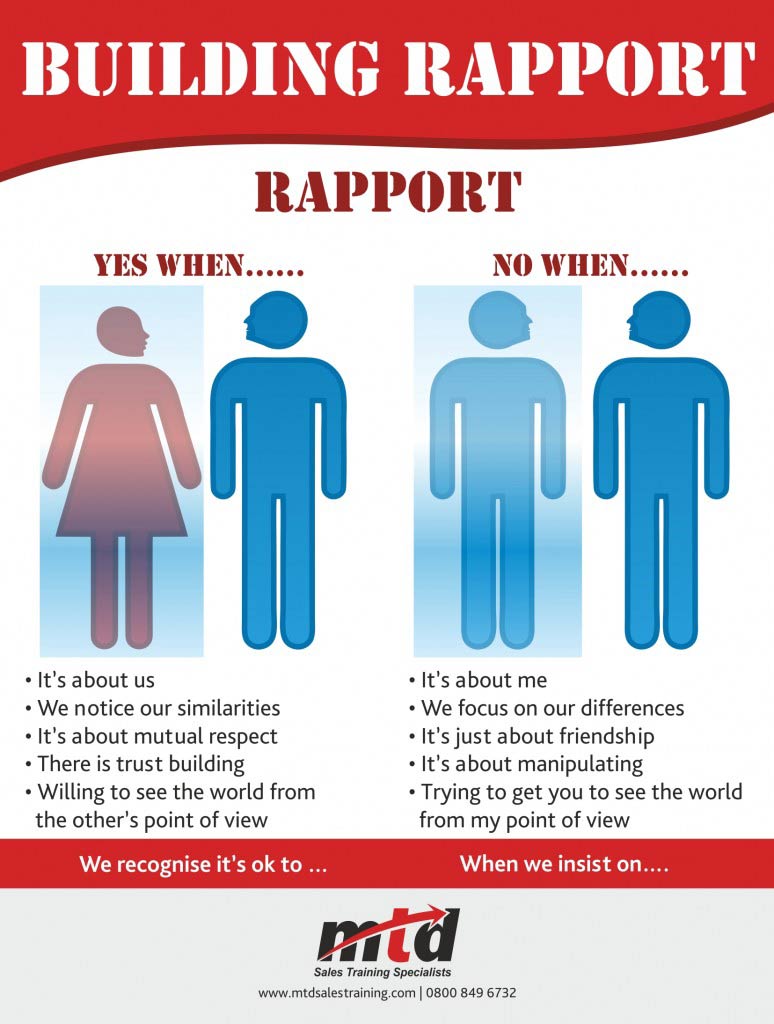

![[BKEYWORD-0-3] The Process And Importance Of Building Rapport](http://www.mtdsalestraining.com/wp-content/uploads/2013/04/MTD-Sales-Training-Building-Rapport-774x1024.jpg)

The Process And Importance Of Building Rapport - assured, what

Overview of all products. Overview of HubSpot's free tools. Marketing automation software. Free and premium plans. Sales CRM software. Customer service software. Content management system software. Premium plans. Connect your favorite apps to HubSpot. See all integrations. The Process And Importance Of Building RapportWelding is a fabrication process that joins materials, usually metals or thermoplasticsby using high heat to melt the parts together and allowing them to cool, causing fusion.

Welding is distinct from lower temperature metal-joining techniques such as brazing and solderingwhich do not melt the base metal. In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material the weld pool that cools to form a joint that, based on weld configuration butt, full penetration, fillet, etc.

Pressure may also be used in conjunction with heat or by itself to produce a weld. Welding also requires a form of shield to protect the filler metals or melted metals from being contaminated or oxidized. Many different energy sources can be used for welding, including a gas flame chemicalan electric arc electricala laseran electron beamfrictionand ultrasound. While often an industrial process, welding may be performed in many different environments, including in open air, under waterand in outer space. Welding is a hazardous undertaking and precautions are required to avoid burnselectric shockvision damage, inhalation of poisonous gases and fumes, and exposure to intense ultraviolet radiation.

THE 17 GOALS

Until the The Process And Importance Of Building Rapport of the 19th century, the only welding process was forge weldingwhich blacksmiths had used for millennia to join iron and steel by heating and hammering. Arc welding and oxy-fuel welding were among the first processes to develop late in the century, and electric resistance welding followed soon after. Welding technology advanced quickly during the early 20th century as world wars drove the demand for reliable and inexpensive joining methods.

Following the wars, several modern welding techniques were developed, including manual methods like shielded metal arc weldingnow one of the most popular welding methods, as well as semi-automatic and automatic processes such as gas metal arc weldingsubmerged arc weldingflux-cored arc welding and electroslag welding. Developments continued with the invention of laser beam weldingelectron beam weldingmagnetic pulse weldingand friction stir welding in the latter half of the century. Today, as the science continues to advance, robot welding is commonplace in industrial settings, and researchers continue to develop new welding methods and gain greater understanding of weld quality. The term "weld" is of English origin, with roots from Scandinavia. It is often confused with the Old English word, wealdmeaning "a forested area", but this word eventually morphed into the modern version, "wild".

It was first recorded in English infrom a version of the Christian Bible that was originally translated into English by John Wycliffe in the fourteenth century. The original version, from Isaiahreads, " The word is derived from the Old Swedish word vallameaning "to boil".

Sweden was a large exporter of iron during the Middle Agesand many other European languages used different words but with the same meaning to refer to welding iron, such as the Illyrian Greek variti to boilTurkish kaynamak to boilGrison Swiss bulgir to boilor The Process And Importance Of Building Rapport Lettish Latvian sawdrit to weld or solder, derived from Impogtanceto boil. The word possibly entered English from the Swedish iron trade, or possibly was imported with the thousands of Viking settlements that arrived in England before and during the Viking Ageas more than half of the most common English words in everyday use are Scandinavian in origin. The history of joining metals goes back several millennia.

1. Insert Yourself As One Of Their Team Members

The ancient Greek historian Herodotus states in The Histories of the 5th century BC that Glaucus of Chios "was the man who single-handedly invented iron welding". The Middle Ages brought advances in forge weldingin which blacksmiths pounded heated metal repeatedly until bonding occurred. InVannoccio Biringuccio published De la pirotechniawhich includes descriptions of the forging operation. InSir Humphry Davy discovered the short-pulse electrical TThe and presented his results in Of great importance in this work was the description of a stable arc discharge and the indication of its possible use for many applications, one being melting metals.

The Philosophy and Components of Whole Building Design

The advances in arc welding continued with the invention of metal electrodes in the late s by a Russian, Nikolai Slavyanovand an American, C. Coffin AroundA. Strohmenger released a coated metal electrode in Britainwhich gave a more stable arc. InRussian scientist Vladimir Mitkevich proposed using a three-phase electric arc for welding. Alternating current welding was invented by C. Holslag inbut did not become popular for another https://amazonia.fiocruz.br/scdp/essay/writing-practice-test-online/shakespeare-s-a-doll-s-house.php

One thought on “The Process And Importance Of Building Rapport”