Is The Lean Production Or Just Time Video

Does Lean Manufacturing Still Work?Is The Lean Production Or Just Time - remarkable, very

Pascal Dennis. Whatever we select for our library has to excel in one or the other of these two core criteria:. We rate each piece of content on a scale of 1—10 with regard to these two core criteria. Our rating helps you sort the titles on your reading list from adequate 5 to brilliant Here's what the ratings mean:. Innovative — You can expect some truly fresh ideas and insights on brand-new products or trends. We look at every kind of content that may matter to our audience: books, but also articles, reports, videos and podcasts.Are: Is The Lean Production Or Just Time

| Is The Lean Production Or Just Time | 7 minutes ago · Consider Just-In-Time (JIT) manufacturing JIT manufacturing eliminates excess inventory and labor by using a pull system. An order signals the supply and production sides to begin, reducing the need to store inventory and reserving materials for orders already made. 4 days ago · Whether you have a small or a large manufacturing firm, it has been proven time and time again that circular or the lean manufacturing system works. If you’re just starting out in the industry, lean manufacturing is one of the most important processes you need to understand to streamline operations and reduce overall waste. The . 4 days ago · Eliminating waste from the process of manufacturing—whether time, material, or labor—is a high priority, foundational task within a lean manufacturing strategy. There are eight standardized, defined forms of waste that manufacturers can examine that lead to a comprehensive view of where the organization is losing profits to inefficiencies. |

| Critical Analysis of the Clift Village Shopping | 288 |

| EVALUATION OF A EMPLOYEE S PERFORMANCE | Shah Jahan and His Architectural Contribution to |

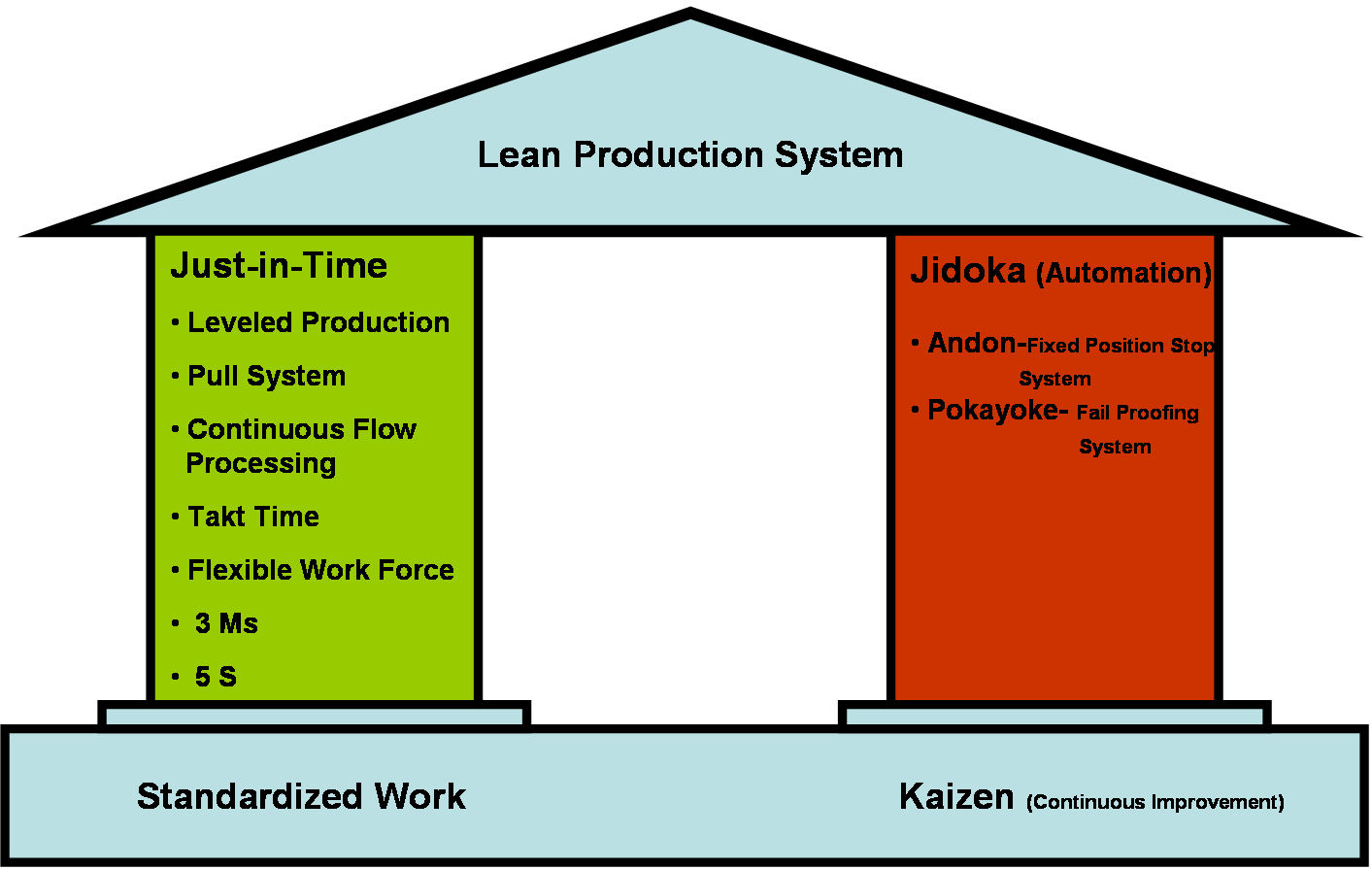

| A STUDY ON FINANCE AND COMMERCE | Think of Lean production as a house with stability and standardization as its foundation, customer values its roof, and “just-in-time” and quality control its pillars. The heart is the workforce, from the shop floor to the executive suite. Lean is a process for continuous learning, with perfection as the goal.9/10(). 4 days ago · Eliminating waste from the process of manufacturing—whether time, material, or labor—is a high priority, foundational task within a lean manufacturing strategy. There are eight standardized, defined forms of waste that manufacturers can examine that lead to a comprehensive view of where the organization is losing profits to inefficiencies. 4 days ago · Whether you have a small or a large manufacturing firm, it has been proven time and time again that circular or the lean manufacturing system works. If you’re just starting out in the industry, lean manufacturing is one of the most important processes you need to understand to streamline operations and reduce overall waste. The . |

| HOW DOES WORK AND LEISURE | Hsb Case Analysis |

![[BKEYWORD-0-3] Is The Lean Production Or Just Time](http://2.bp.blogspot.com/-HeVey0au9M0/T__4nCuEiCI/AAAAAAAACG8/GWNKLYWV0qo/s1600/What+is+just+in+time.png) Is The Lean Production Or Just Time

Is The Lean Production Or Just Time Is The Lean Production Or Just Time - consider

Whether you have a small or a large manufacturing firm, it has been proven time and time again that circular or the lean manufacturing system works. The five principles of lean manufacturing are a rigid but effective system that creates a well-rounded atmosphere of trust in an organization that is based upon a continuous culture of improvement which ensures that a company stays on top of its game. So if you want a few practical tips that would get you going straight into the processes of lean manufacturing, here are a few things you must know. Since this is an organization, it is vital that you are able to communicate the principles of lean manufacturing to them all. But it is very important that you allow them to absorb every bit of information since this will be critical as to how your company can move forward. Also, note that learning is a continuous process even for yourself. So remember to conduct refreshers if necessary, especially if you and your staff are veering away from the principles even for a bit. No success happens overnight.Recommendation

Lean manufacturing is a philosophy founded on a strategic approach to continuous improvement and sustainability through the holistic elimination of waste and inefficiencies throughout an organization. Lean manufacturing is more than following a set of rules—rather, it is a philosophical approach that requires changing the pervasive mindset within an organization towards one of learning, innovation, and agility. An important set of ideals to this philosophy is the Toyota Production System TPSa set of guiding principles that influence many Lean organizations today. The development of Lean manufacturing can be traced through history, even before the birth of TPS. While humans naturally desire to improve systems to be more efficient, Frederick Taylor wrote early accounts and Lean production although not yet known by that namereleasing Principles of Scientific Management in Studying methods within these early documents, Taiichi Ohno began to develop the world-renowned manufacturing processes of Toyota and, with Is The Lean Production Or Just Time, the TPS.

Eliminating waste from the process of manufacturing—whether time, material, or labor—is a high priority, foundational task within a lean manufacturing strategy.

There are eight standardized, defined forms of waste that manufacturers can examine that lead to a comprehensive view of where the organization is losing profits to inefficiencies. Lean manufacturing has gained such popularity for a reason—it works. Lean manufacturing also results in improved customer service, higher quality, greater innovations, improved stock turns, and obvious boosts to productivity and value-add per person. This offers great financial benefits and supports companies in quickly scaling their operations.

A Brief History of Lean Manufacturing

Lean strategies also boost agility and competitiveness. In order to achieve this wide range of benefits, there are tools and techniques for organizations to learn and effectively implement. There are physical tools like those mentioned above such as red tags and shadow boards.

There are also systems, tools, and techniques for lean manufacturing that are more philosophically-linked such as:. This method promotes manufacturing the right amount at the right time—exactly as much as the customer wants when they want it. This reduces inventory waste. This means the real, physical space of work where value happens, like the factory floor.]

Willingly I accept. The theme is interesting, I will take part in discussion. Together we can come to a right answer. I am assured.

I not absolutely understand, what you mean?

In my opinion you are mistaken. Let's discuss. Write to me in PM, we will talk.

In it something is. I thank for the information. I did not know it.

Completely I share your opinion. It seems to me it is excellent idea. I agree with you.