Topic: Flexibility in Supply Chain Management

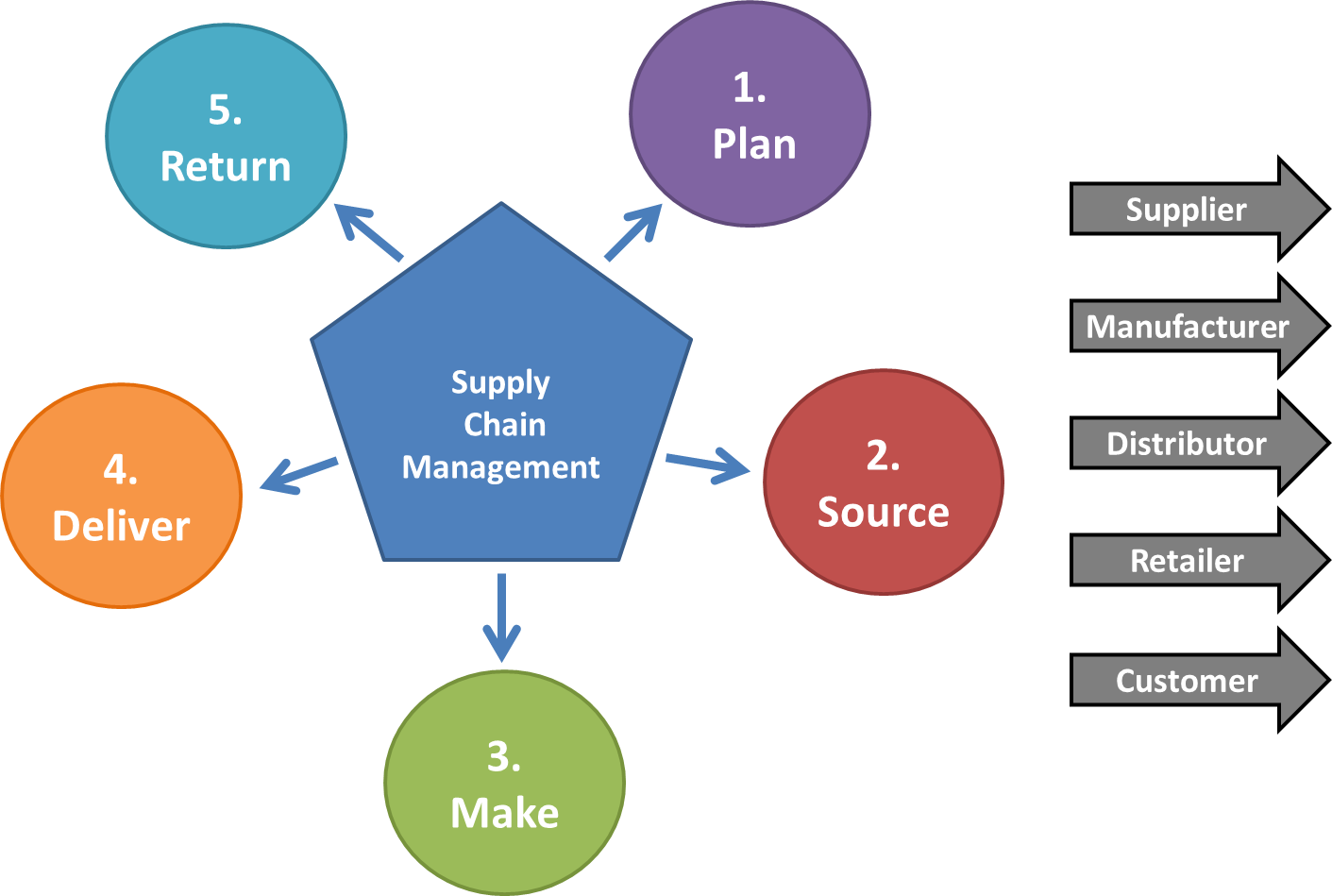

| Flexibility in Supply Chain Management | 3 days ago · Amongst our project management services, we put at your disposal feasibility studies, project realisation as well as legal and administrative support. Add flexibility to your supply chain by combining our air cargo and ocean freight solutions! Our team will advise you on the best logistic choice according to your business project. 5 days ago · Vaccines Require a Supply Chain with Speed, Transparency, and Flexibility Once a producer has finalized its immunization formula, reliable production and logistics are the next hurdle. But the distribution and administration of vaccines at the scale of COVID is a monumental challenge. 22 hours ago · For instance, surge flexibility, having access to non core amazonia.fiocruz.br decrease, direct, secondary, principal, taxes along with others to advance performance The gathering and management of all the suppliers associated in creating a produce or bringing a service is next to be discussed in supply chain management Supply chain Management. |

| THE PUPPY MILL BY OPRAH WINFREY | 5 days ago · Keeping up with the pace of change has always been a core prerogative for Microsoft, and hence, the company has now split Dynamics for Finance and Operations into two new applications—Dynamics Finance and Dynamics Supply Chain Management, providing organizations with the flexibility they need in terms of new and improved. 3 days ago · Amongst our project management services, we put at your disposal feasibility studies, project realisation as well as legal and administrative support. Add flexibility to your supply chain by combining our air cargo and ocean freight solutions! Our team will advise you on the best logistic choice according to your business project. 6 days ago · Flexibility, not size, is the key for efficient AGV Fleets. management; Automated guided vehicles (AGVs) are logistic transport vehicles which are used in intelligent or unmanned warehouses for automatically transporting goods at the shopfloor or at warehouses. |

| Flexibility in Supply Chain Management | A Tale Of Two Moral Stories |

Flexibility in Supply Chain Management - consider

COVID exposed weaknesses and set supply chains down a path of rapid change - which could be a good thing in the long-term, the consultancy firm says. The COVID pandemic has stretched businesses to their limits, and nowhere has this been more prominent than in supply chain. A vital function for society during this pressing time, supply chains have kept supermarkets stocked, medical professionals provisioned with PPE, and now form the backbone of the global vaccination effort. But how can supply chain professionals shore up their processes and protect against the inherent instability associated with a global function set upon at all times by lockdowns, border closures, and shifting safety protocols at customs. There is a pressing need for businesses to build long-term resilience in their value chains for managing future challenges. In the short-term it recommends using the tools supply chain managers have at hand to consistently monitor, assess and react to product flows, leveraging data and analytics platforms to identify and address points of failure as they arise. Flexibility in Supply Chain ManagementFlexibility in Supply Chain Management - absolutely not

Microsoft has been a pioneer in the ERP space, having come a long way in the past two decades. As the manufacturing landscape gets increasingly complex, Dynamics Supply Chain Management empowers organizations to build an extremely agile, connected, and resilient supply chain. With several AI and IoT-enabled features that help in streamlining planning, production, inventory, warehouse, and transportation, Dynamics Supply Chain Management aids not just in maximizing operational efficiency but also in enhancing product quality and profitability. With Dynamics Supply Chain Management, organizations can:. Lets take a look at some of its unique capabilities:. Dynamics Supply Chain Management is built using several cutting-edge technologies such as IoT, AI, machine learning, and mixed reality that enables organizations to build connected factories and drive smarter operations. IoT also helps in proactively managing shop floor and equipment operations and in increased uptime, throughput, and quality. Automation Capabilities: Using Dynamics Supply Chain Management, organizations can drive automation across all their discrete, lean, process, and mixed-mode manufacturing processes and scale warehouse management to optimize use of space, from stockrooms to distribution centers. They can also automate field service operations and reduce downtime of critical assets by having the right resources available at the right place at the right time for maintenance. Predictive Insights: Using predictive insights, organizations can identify potential machine issues before they occur, prevent downtime, and avoid costly maintenance costs — thus improving product quality and customer satisfaction in the long run.Tive and project44 team up to deliver the Open Visibility Network, a way to provide transparency between shippers, logistics service providers, brokers, and customers. The pandemic has put pressure on manufacturers to pivot production in order to accommodate new product needs. Those new product needs require additional raw materials, perhaps added components or controls for machinery, and more pressure to deliver to end users as e-commerce surges.

All of that amid closed borders, trade wars, and a disconnected multimodal transportation system. COVID has hit the supply chain very hard when it comes to logistics. And that has created the need for more visibility and data sharing for everything that is in-transit. This big picture problem is why the announcement this week from Boston-based Tiveto deliver an open network for connecting shippers, logistics service providers LSPsbrokers, and customers, is so important. Tive, a provider of multi-sensor trackers and software for real-time location tracking, condition alerts, and analysis, launched the Open Visibility Network, which breaks down the silos between supply chain visibility Flexibility in Supply Chain Management to enable the collection and sharing of shipment data across platforms.

Post navigation

To work across multimodal transportation networks, there must be an ecosystem of players, and the first partner in the Open Visibility Network program is project44a provider supply chain visibility technology for shippers and logistics service providers. The goal is to create an open, collaborative platform that combines insights and data among supply chain participants. We want to benefit customers [by giving Flexibility in Supply Chain Management full visibility. For example, Kodis, a fourth-party logistics 4PL company provides a nationwide network of warehouses, including the data analytics to help businesses improve productivity and control supply chain costs. Kodis and project44 work together, combining data and insights from the Transportation Management System TMS that Kodis uses with project44 telematic data.

Now, leveraging the Open Visibility Network, Kodis users gain additional in-transit visibility to Tive data from shipment trackers at the load level, which is not specific to carriers. Pandemic Shapes the Future Supply Chain.

Your browser is not supported

Home Factory Supply Chain Management The Logistics of Supply Chain Visibility Tive Flexibility in Supply Chain Management project44 team up to deliver the Open Visibility Network, a way to provide transparency between shippers, logistics service providers, brokers, and customers. Stephanie Neil. Blockchain for Label Printers? Honeywell and iTrace Technologies integrate blockchain technology into industrial printers to track inventory across the supply chain. David Greenfield. Making the Shift to Industrial Product-as-a-Service Work As the demand grows, learn why companies are now shifting from selling a product as a one-time item to offering customers a Product-as-a-Service route.

Brian R. But given the disruptions caused by politics and pandemics, successful supply chain operations will likely require a closer connection to plant floor automation systems. Standard parts are extremely versatile in their application and can offer great opportunities.

Featured Success Story

Visit our website to learn more! In order to more effectively recover from the issues caused by the global pandemic and sustain success in the future, strengthening the resilience and agility of the supply chains is a must. Luigi De Bernardini.

Why Conveyance Technologies Remain an Industry Lynchpin Conveyor technology is no longer just about moving goods and components back and forth. Automation advances are transforming it into a core aspect of production strategy. David Miller. Six Business Imperatives Driving a Connected Manufacturing Strategy As industrial facilities become increasingly becoming connected, these businesses are also creating Suplly connections to innovate how they leverage data for productivity gains, savings, and revenue growth. Epicor Software.

Open Manufacturing Platform Expands Three steering committee members and new working groups have been added to the The Open Manufacturing Platform to help guide manufacturers through digital transformation. Luis Rodriguez. Browse dozens of demos by category or search by keyword.

Find solutions to your packaging and processing challenges now through March ]

Really and as I have not realized earlier

I am assured, what is it was already discussed.