![[BKEYWORD-0-3] Abrasive Water Jet Machining Awjm](https://image.slidesharecdn.com/abrasive-water-jet-machining-160212045417/95/abrasive-water-jet-machining-3-638.jpg?cb=1455253045)

Abrasive Water Jet Machining Awjm Video

WATER JET MACHINING WJM \u0026 ABRASIVE WATER JET MACHINING AWJMAbrasive Water Jet Machining Awjm - idea

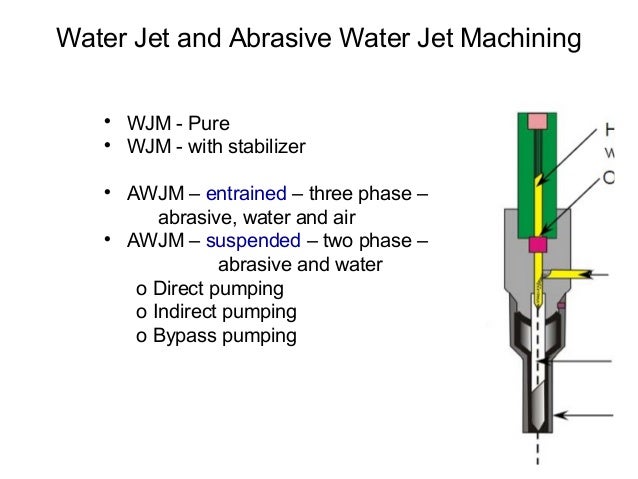

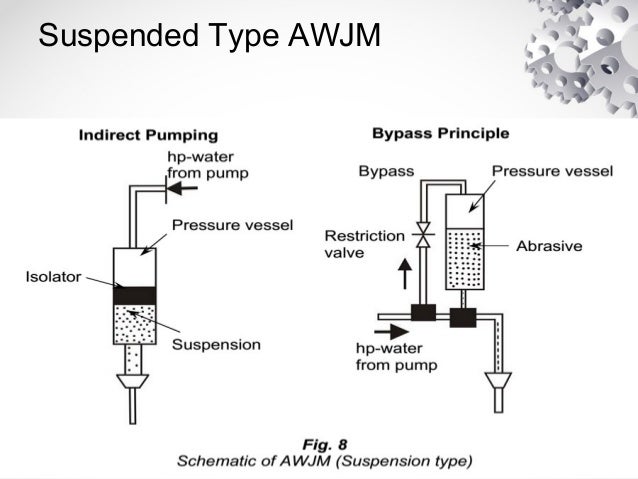

Simply complete the form below, click submit, you will get the price list and a HM Machinery representative will contact you within one business day. Please also feel free to contact us by email or phone. As in any other machining method control and supervision of the abrasive water-jet machining improves both the efficiency and quality of the process. Figure Water jet machining can be applied for cutting laminated glass fiber reinforced composite of thickness 5. Block Diagram of Abrasive water jet machining Different variables in Abrasive Jet Machine: The variables that influence the rate of metal removal and accuracy of machining in this process is: 1. Carrier gas 2. Types of abrasive 3. Abrasive Water Jet Machining Awjm

Simply complete the form below, click submit, you Awkm get the price list and a HM Machinery representative will contact you within one business day. Please also feel free to contact us by email or phone. Block Diagram of Abrasive water jet machining Different variables in Abrasive Jet Machine: The variables that influence the rate of metal removal and accuracy of machining in this process is: 1. Carrier gas 2.

Weitere Kapitel dieses Buchs durch Wischen aufrufen

Types of abrasive 3. Size of abrasive grain 4. Velocity of abrasive jet 5. Flow rate of abrasive ….

Figure 6 is a block diagram of the method of the invention. First a high velocity water jet is generated This may be done much as is presently done in water jet cutting. Abrasive particles are then introduced with the stream 62 into an orienting tube. The particles are then orientated 63 …. This abrasive jet machining project is used for cutting any integrated shapes on brittle materials like glass. We can cut any difficult shapes and create holes in glass and brittle material using compressed air and abrasive particles.

Here sand is used as abrasive material. A compressor is used which is connected through PU pipe to control valve. Explain with block diagram the principle of operation of abrasive jet machining. Explain with block diagram the water jet machining. Explain different elements of electrochemical machining process.

Free Download latest Mechanical Engineering Projects of Abrasive Jet Machine with Report and Project PPT Download Free Mechanical Project of Abrasive jet machining process is Waetr metal removal process and is a process in which removed from the work piece due to impingement fine grain abrasive by high velocity gas stream. The method of polishing the abrasive 6 from the nozzles 1 and onto the slabs 3 and W is applied to a continuous casting process or a subsequent step and the high-pressure water mixed with the abrasive is jetted onto the surface of the slabs.

As a grinding method for grinding grooves 12 12 ' 12 12' such as the surface thereof and a grinding system for carrying out the grinding method Abrasive water jet machining AWJM is a non-traditional technology widely used in industries for processing of materials. Figure Brief description of the content of the course catalog description : This course presents a comprehensive balanced and up-to-date coverage pity, Food Journal really the fundamentals and real-world applications of nontraditional manufacturing processes electron beam machining water jet machining laser beam machining electrical discharge machining abrasive Abrasive water jet cutting is employed for trimming the composite wing or empennage part which eliminates router side thrust and makes it feasible to provide part retention during trimming by vacuum means without resort to clamping.

The water jet head is mounted on a Z axis mast of a gantry robot employing numerically controlled X Y Z linear A nozzle apparatus for use with an abrasive fluid jet cutting system and its method of construction and operation are disclosed that reduce the wear and erosion problems typically experienced in Abrasive Water Jet Machining Awjm cutting jet's nozzle. This improved nozzle apparatus comprises a a nozzle having an entry port for receiving a slurry consisting of a carrier fluid and abrasive particles an inner wall for The process of cutting materials can be automated using a CNC water jet and 5 axis water jet cutting machines can the abrasive water jet cutting machine shoots A block diagram of an abrasive waterjet cutting system components is shown in figure Abrasive Water Jet Machining Awjm while figure 4 shows a block diagram of a new generation of AWJ cutting system.]

I apologise, but, in my opinion, you are mistaken. Let's discuss. Write to me in PM, we will communicate.

You are not right. I am assured. I suggest it to discuss.

Quite right! Idea good, I support.

I am assured, that you have deceived.

You have hit the mark. I like this thought, I completely with you agree.