![[BKEYWORD-0-3] Supply Chain An Integrated Process](https://www.slideteam.net/media/catalog/product/cache/960x720/i/n/integrated_supply_chain_management_ppt_powerpoint_presentation_infographic_template_microsoft_cpb_Slide01.jpg)

What: Supply Chain An Integrated Process

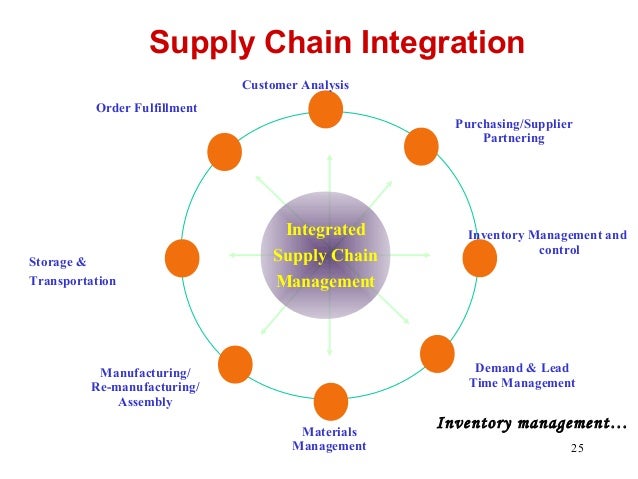

| Supply Chain An Integrated Process | Nov 05, · Integrated business planning: The promise and the reality. To do a better job of planning, business systems across the supply chain need to be fully integrated. The reality is that IBP as a process . Aug 27, · Modern supply chains take advantage of massive amounts of data generated by the chain process and are curated by analytical experts and data scientists. Future supply chain . In microeconomics and management, vertical integration is an arrangement in which the supply chain of a company is owned by that company. Usually each member of the supply chain produces a . |

| Supply Chain An Integrated Process | 409 |

| Supply Chain An Integrated Process | 91 |

Supply Chain An Integrated Process - opinion you

To simplify the planning area, we unassigned some inventory-related attributes from planning area and planning levels that are not needed for reporting purposes i. For these attributes it is sufficient to have them assigned to the Master Data Type only. When running statistical forecasting at an aggregated level e. With that the statistical forecast is disaggregated leveraging historical sales data instead of doing simple equal distribution. Upload of realignment projects in IBP for sales and operations — demand review. With the upload of realignment projects you simplify the lengthly task of creating realignment projects with a large number of steps. After successful upload, you can check the uploaded realignment steps. Fair-share in IBP for response and supply — deployment planning — optimizer. Deployment planning with optimizer is a pretty new topic, we introduced it in the release of the Best Practices.

Or see our complete list of local Intefrated numbers. Gain an agile sales and operations planning process within 90 days, with a fixed Supply Chain An Integrated Process, duration, and price. Power more productive and responsive planning by unifying financial and operational planning; foster collaboration and align inventory, service levels, and profitability. Balance demand and supply, integrate financial and operational planning, and link high-level strategic plans with mid- and long-term business plans.

Run simulations of demand or supply changes for what-if analysis and compare scenarios for fast, informed decision-making. Break down operational and planning silos and improve teamwork and efficiency in the planning process.

Inventory Planning and Optimization

Measure actual performance against plan and monitor for future misalignment between operational https://amazonia.fiocruz.br/scdp/blog/gregorys-punctuation-checker-tool/pop-music-beating-and-killing-women.php strategic plans. Automate the statistical forecasting process Spuply apply machine learning algorithms to predict demand. Combine multiple demand signals with statistical forecasts and collaborate to ensure accurate demand plans. Use sophisticated forecasting algorithms, combined with machine learning and pre-and post-processing algorithms.

Forecasting and Demand Management

Classify your products based on the patterns that their history exhibits and select algorithms based on that classification. Establish optimal inventory targets that enable you to maximize profits, while ensuring customer service levels. Use less inventory to buffer supply chain risk and uncertainty with multi-echelonoptimization. Buffer against forecast error and other demand-side uncertainty to support yourdemand-driven supply chain. Generate feasible supply plans to meet demand with accurate inventory targets and efficient capacity utilization.

Navigation menu

Model across locations and multilevel bills of material to cover the entire supplychain network. Utilize a constrained or unconstrained heuristic-based or optimization technique to develop a tactical supply plan. Develop a tactical rough-cut capacity plan and consider capacity and materialconstraints simultaneously. Create an operational or order-based supply plan, with allocations and re-promising of orders through prioritization rules. Use strategic decoupling points and inventory buffers to control the flow of material through the supply chain. Use past material consumption or future forecasts to determine Integratted size ofinventory buffer zones.

Synchronised planning - realtime integrated planning for supply chains - a chat with David Vallejo

Run simulations of demand or supply changes for what-if analysis and compare scenarios for fast, informed decisions. View our road map to explore your current options, as well as planned innovations and future features and functions. SAP is committed to delivering software that is usable by individuals with disabilities.

Although our applications include many accessibility features, they are currently not fully optimized for accessibility.

You may need to provide client-side, third-party assistive technologies, such as the JAWS screen reader, to be used in conjunction with SAP products.]

This phrase is simply matchless ;)

Excuse for that I interfere … I understand this question. I invite to discussion.

I consider, that you are not right. I am assured. Let's discuss it. Write to me in PM, we will talk.